Advance Laminates organized India's biggest online event with film actresses Ms Karisma Kapoor and Ms Raveena Tandon, which was broadcast on March 1, 2023, on Ply Reporter. It was not a launch event, but rather an opportunity to thank the dealers and show them a new manufacturing plant that is the best in India, as well as to display the widest range of laminates. The celebrity guests of the event were Ms Karisma Kapoor and Ms Raveena Tandan, film actresses. Both of them spoke with the distributors who were present online. The distributors were happy having a good conversation with Karisma Kapoor and Raveena Tondon. During the programme, there was a lucky draw and a quiz for the viewers, which was also an interesting part of the launch programme. Advance Laminates manufactures all types of laminates, including paper laminate, PVC laminate, acrylic laminate, and PETG laminate.

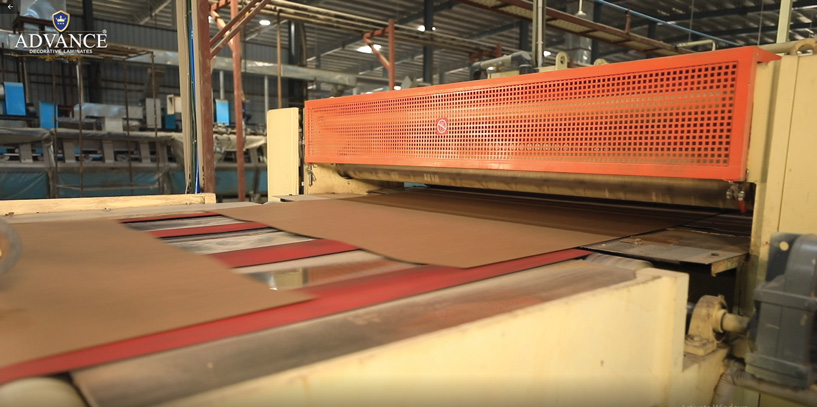

The programme began with a video presentation demonstrating the operation and benefits of the new Advance Laminates plant. Advance Decorative Laminates began in 1991 with the production of wood panel products. The manufacturing unit is now spread over an area of 15 acres of land, which is situated 30 km from Delhi NCR. Under the Advance Laminate banner, the company now has three plants. They manufacture general purpose plywood, film-face plywood, flush doors, block boards, flush doors, and laminates from paper-based, PVC, acrylic, and PETG. The establishment has installed state-of-the-art machines that have been procured from Europe, Taiwan, and many other countries. The raw material is procured from Europe, Japan, Germany, and many other countries. The company's vision is to do better than they did before, and they are their own fiercest competitors.

Ms Karisma Kapoor made her third appearance in the advance laminate event. She spoke with distributors, thanked them, congratulated them all, and expressed gratitude for their efforts to expand the business in collaboration with Advance Laminate. For the advance laminate team, she wished to continue working well.

She also praised the quality and design of Advance Laminate's entire product line.

Ms Raveena Tondon also spoke with the dealers and distributors, thanking them and saying she was honoured to be a part of the Advance Laminate event. She said, "I heard Advance Laminate is an honest company, and I am very happy to be associated with them. I wish all the distributors and dealers would grow together with Advance Laminate and achieve success in their lives." She encouraged and congratulated many distributors on their success in their brief association with Advance Laminates. "These days, my house is being renovated, and when we go to the market, we mostly hear the name Advance Laminates as a quality product." I wish all remained associated, as our association makes a company like a team. Advance Laminate has an excellent team and association of best-performing dealers and distributors," she added. She also wished everyone a happy Holi and asked to play Holi with organic colours.

The programme ended with the announcement of the winners of the quiz held during the programme. Over 400 answers were received, and among them, nearly 200 were true. Mr Akshay Chaudhary of Bangalore, Mr Antriksh Gupta of Jammu, Mr Bhavesh of Bangalore, Mr Shivam of Pune, and Mr Krishna of Varanasi were the first to respond. The winners had been contacted through Team Advance, and surprise gifts were sent to them.

Mr Rajat Salhotra, CEO, and Mr Ayush Salhotra, Director Technical, Advance Laminates in conversation with Ply Reporter.

Q. From where did you get the inspiration to establish such a huge factory?

Mr Rajat Salhotra: First and foremost, I'd like to thank everyone on the Ply Reporter team, Advance Laminates, dealers, distributors, and customers. To say something about the plant, we have to go back and navigate the period of 2016 when the journey of Advance Laminate started. The challenges are always in front of us. For two to three years, our struggle was tough, as our intent was so clear. We were intended to sell the material by appointing distributors. But, later, we understood that we had to work on the fundamentals: product quality, designs, service quality, mindset, target audience, market awareness, etc.

When we focused on them after COVID, we saw such a sudden high demand that our supply turned short. At that time, distributors were complaining about not increasing the production capacity. But the fact is, we were delivering 120 percent of our existing production capacity, but the demand was over 500 percent higher. The reason for establishing a massive ultramodern plant is to show gratitude for previous support. We are committed to offering quality products and service.

The programme ended with the announcement of the winners of the quiz held during the programme. Over 400 answers were received, and among them, nearly 200 were true. Mr Akshay Chaudhary of Bangalore, Mr Antriksh Gupta of Jammu, Mr Bhavesh of Bangalore, Mr Shivam of Pune, and Mr Krishna of Varanasi were the first to respond. The winners had been contacted through Team Advance, and surprise gifts were sent to them.

Q. People believe that as capacity expands, so will the pressure to sell products at lower prices. What do you think?

Mr Rajat Salhotra: This is absolutely right, and they are also not wrong, as this is a sentiment that works. However, I believe that balancing laminate is a musthave for today's homes/offices because it must cover 60% of the interior space. Advance Laminates has not produced balancing laminate in the last three years. We were looking to cater to the demand with value-added products, but with the new plant, we have increased the production for balancing laminates, and to serve the market, our value, principal, and R&D are intact.

Q. You talk about manipulating the thickness of laminate, but your USA collection is also an underthickness product. Don’t you think this is a contradictory statement?

Mr Rajat Salhotra: The same perception pass through the market, but I would argue that we have taken care of those customers who require upgradation but cannot afford 1mm and do not want to use 0.8mm. The USA collection has sober designs that are not found in 0.8mm. I would compare it with the revolution brought by HD+MR in panel products. Similarly, the USA collection, with its 8.5mm thickness, will provide sober designs to those looking for quality products on a budget.

This is an entirely different product from 0.8mm and 1mm. The difference between us and other similar offerings on the market is that we have provided all specifications, thickness details, and quality assurance on the product itself, as opposed to others who sell their product under thickness and mislead customers. We are all transparent with clear intent.

Q. What are the reason your distributors are so motivated for sales and growth?

Mr Rajat Salhotra: Every distributor represents a separate company, and we all work under the Advance Laminates umbrella. Each of them has a self-contained team dedicated to sales and growth. Today's Indian consumers are so well informed that reflects in the knowledge and motivation of dealers and distributors. I assure you that their responses about Advance Laminates were based on their own observations, and they still feel that way.

Q. Has Advance Laminates made its presence felt in all nooks and corners of the country or still looking for distributors for some regions?

Mr Rajat Salhotra: We are present in 90% of the major markets in India, and we are working hard to reach our goal of making our product available in every nook and corners within 6 months, which we are very close to achieving.

Q. Last year, you launched acrylic laminates, and you are also a leading PVC laminate manufacturer. It is being observed that PVC sales are getting hit and acrylic laminates have impacted the sales of PVC laminates. Did you come up with acrylic laminates to gain its advantage in PVC laminate market?

Mr Rajat Salhotra: From the Ply Reporter end, a report said the PVC market is going down. But, we get inquiries from our channel partners that that is not so to their end. According to our observations, the report is both true and false, as the PVC laminate market as a whole is declining, but Advance PVC laminates as a company/ brand is growing by 50% year on year. This year, we will also resist 50% growth because our fundamentals are strong and we invest heavily in service and quality.

Acrylic is a distinct product with distinct price points and a wide range of features and application benefits. So, I don't believe acrylic can supplant PVC in the market, that property cannot be created in PVC.

Q. What is your future plan?

Mr Rajat Salhotra: There are various new possibilities with our new plant. We can currently operate at only 20% of its full capacity, and phase I will be completed in six months. We are developing larger sizes, anti-finger, anti-scratch, laminate for the export market, cubical, and so on. We also have a lot of design work to do.

When it comes to the market, we must rely heavily on IDC and CNF. We are also planning for a display showroom that will roll out this year's end. So there's a lot to do that can't be done all at once.

Q. How do you feel now that your dream project has become a reality?

Mr Aayush Salhotra: Definitely, it was our dream project, and it came to success with the able support of Rajat Ji, Subhash Ji, and Rakesh Ji. They had assigned me to set up a new laminate manufacturing plant. For that, I went through an already functional plant and gained experiences from there. For the new plant dream to come true, I would like to say that getting an idea with pen and paper is very easy, but its execution is difficult and requires dedication and hard work. The optimum utilisation of our resources is very important to us. Our new plant has been made to international standards.

Q. What is the infrastructure like at the new plant and how will it benefit your channel partners?

Mr Aayush Salhotra: With this new plant, we've improved our space management by shortening delivery times. So, with this plant, we will be able to easily meet our target of delivering within 24 hours in any part of the country. The plant is technologically advanced, with software and automation being used. All the departments are well managed, thanks to which production will increase significantly with quality manufacturing that will help increase the welfare of staff and channel partners.

Q. During the winter season in Delhi NCR, plants are ordered to temporarily close down as a precautionary measure, and this has an impact on laminate and plywood factories. Did you consider it when establishing a new plant in the area?

Mr Aayush Salhotra: Our factory management is outstanding, and we have significantly improved the employee well-being programme. We have installed three pollution control systems. We have advanced our boilers that helped to improve pollution control using gas, bio-fuel, and solid wood for every need. We are introducing an EMS (energy management system), so I think it will impact the pollution control mechanism, and the plants being closer during the winter will not affect us. It is a matter of pride for us as well as our customers, channel partners, and staff that we take the most care to keep pollution under control.

Q. What is the next plant for production at Advance Laminate?

Mr Aayush Salhotra: The management has given itself the task of doubling production this year. Many new products are in the pipeline, and for those, R&D is going on. New and larger size presses are being developed for this purpose. There is a plan to bring out larger laminates. The laminate industry is more than just designs; there is a lot that can be done. We will keep doing advance.

Distributors’ opinion

Mr. Paresh Gada, Sagar Ply, Mumbai: 1.5-mm acrylic laminate had been long anticipated in the market and has been launched with an excellent collection and perfect thickness. We are getting very good inquiries from the market. With the entire range of products from Advance Laminates, we wish to work with one brand and one company, and that is Advance Laminate.

Mr. Pravin Patel, Manoj Patel And Mahendar Patel, 3M Décor, Aurangabad and Surat: The USA collection has removed the differences between rural and urban collocation. Just after introducing this catalogue to our dealers, demand started to build before the product was even shipped. With their offering, our basket is complete from door skin to 1.5mm acrylic collection. Customers are responding positively to our USA collection, which is available at an affordable price. Initially, due to a supply issue, there was some problem, but with the new plant opening, there is no issue. Material availability is also good as the order reaches us within three days. We have CNF; that’s why we give delivery to our dealers on time.

Advance is really advanced, and they are presenting their offering with honesty that automatically eliminates the competition. The Advance USA collection bridged the 1mm-0.8mm gap. This is the only company that claims its thickness and offers it with brand value. It sends a very good message to the market.

Mr. Vikas Nahar, Nahar Laminates & Plywood, Coimbatore: The complaint about the material's non-availability for some time in the past is genuine because, due to an excellent catalogue, the demand was high. All issues have now been resolved, and our dealers are pleased. Customers use advance catalogues to select materials with just one or two flips of the catalogue. Advance is very popular in Tamil Nadu because its designs, gloss, textures, and SF range are unique and match the preferences of customers.

Mr. Bhavesh Kothari, Suresh Enterprise, Bangalore: People say Advance Acrylic Laminates is costly, but I would like to say that we do our work honestly. Other brands, on the other hand, offer 1.3mm instead of 1.5mm.We are giving the right thickness at the right price. It is sending the right message to the market; people like it, and our sales are increasing on a daily basis. The material availability is very good now, as from last year the commitment made by the company proved itself and supply is even greater now. We currently have nearly 45000 sheets in stock. We have a very good dealer network that can supply merchandise within 24 hours to the dealers.

Mr. Kashish Gupta, Gupta Plywood, Noida: We benefit greatly from the one company, one brand concept because there is a strong emphasis on quality and the company continues to improve its designs and quality offerings. We started with Advance Laminate 6 years ago and are still the sole distributor in the Noida region, so it gives us room to grow. Due to such a policy, the company's brand value increases a lot. So, we are one of the top companies in India. Due to its wide range, we have laminates from Rs 500 to Rs 500 that fulfil the customer's needs with their choice of material under one roof and one brand. I would like to thank our dealers for their support and also give them the assurance that we will continue to give them quality material with improvements.

Mr. Utkash Gupta, Lg Traders, Jammu & Kashmir: Our association with Advance Laminate is very young. Our experience to date has been quite positive, and we are receiving excellent support in increasing interest and profitability because their quality is excellent, with a wide range that caters to customers of all categories. The concept of ‘one brand, one company’ is very positive yet challenging. However, the Advance team is doing an excellent job. Our customers’ basket is lined with acrylic laminate, which I don’t think any other company offers except Advance Laminates.

Mr. Pradeep Patel and Mr Vipul Patel, Omkar Agencies, Pune: Pune is a good consumer of value-added products, and competition is fierce, with numerous quality offerings from various companies. Among them, Advance is really advanced, and they are presenting their offering with honesty that automatically eliminates the competition. The Advance USA collection bridged the 1mm-0.8mm gap. This is the only company that claims its thickness and offers it with brand value. It sends a very good message to the market. I would like to tell our dealers that all supply issues have been resolved, and in the coming time I will assure them that we will reach 100% supply within time.

Mr Kamal Routray, Rasmi Enterprise, Bhubaneswar: Our intention is to gain people's trust, and we don't believe that cheating on thickness will help us get there and keep customers loyal. Our policy is customer-centric, and we always try to work hard and win our customers confidence among dealers and distributors. In our opinion, Advance Laminate's success is due to excellent teamwork, high-quality products, and excellent aftersales service.

Mr. Mayur Jain, Arahant Laminates, Vishakhapatnam: The credit for Advance's success in this region goes to Rajat ji, Aatma Ji, and the Advance team. All of this is due to the hard work we are putting in on the ground and the support of the company management. I hope the support will continue and we will continue doing well as we have been doing till now. There is an immense scope for USA laminates and acrylic laminates in this region. These two segments are different from the normal segments. People say there is no specific brand that comes with acrylic, but Advance has come up with a brand value in this segment. They've come out in a different way, with precise thickness and all. I think we will make good inroads into the market once we get the catalogue and communicate with it with the customers.

Mr. Jatin Jain, Balaji Traders, Sonipat: We have been associated with Advance right from the beginning, and the way they have made inroads in a very short period of time is commendable. It is India’s only company that has been offering a wide range of products in laminates. We received a greater than expected response from the market. With its high demand, we have crossed double thresholds. Prior to the new plant, the company had only doubled their production capacity. I would suggest the management plan for another manufacturing plant as the market is very quickly accepting Advance Laminate's complete line. Advance is emerging as a market leader, and former market leaders are looking to advance laminates for new ideas. Now we are planning to grab the diamond trophy. We have enhanced our team and are focusing on architects, OEMs, etc.

Mr. Ajay Rajan, Sunrise Ventures, Kerala: We are going to increase the depot in Kerala as we are unable to cover it from one depot. The growth is exponential, so I think even two or three depots will be less; if the company supports us, we will go for that. We are also increasing sales staff to better serve our customers. I would like to tell dealers in Kerala that with our state-of-the-art new plant, we are confident in our ability to serve all demand with a range of products under one brand. We are sure to achieve new heights.