Aluminum Coil is the main raw material for making Aluminum Composite Panels that are used in Façade and signage sector. The Aluminum composite panel manufacturers in India have also grown especially during the last 5 years due to growing demand in various markets. The Aluminum coil is used in top coating is a key material that has witnessed a sharp jump in prices by around 40% during the last two months till writing this report. With sharpshooting prices, ACP manufacturing companies are badly hit, thus affecting the ACP manufacturing and supplies in markets. A report…

The ACP manufacturing sector is at present on the verge to collapse where, if it shuts down, there will be losses and if it runs, there will be losses. Since Aluminum Coils contribute to be approximately 35 to 40 % of raw materials input cost for ACP manufacturing, there is no way other than increasing the prices especially, when the Indian ACP Industry is heavily dependent on imported Coils from China.

According to the majority of industries in ACP in India, the major imports of Aluminum coil are coming from one source country i.e. China. Mr Goel says that 97% of material is coming from China, and there is supply issues coupled with freight factors so there is no respite. The Ply Reporter spoke to various suppliers and trade experts who suggest that ‘the price for aluminum coil will not go down till November or Diwali.

Mr Mohit Goel, Owner of Balaji Overseas and an Aluminium Coil supplier said, “The prices of raw material such as Aluminium coil for the ACP industry does not seem to come down any time soon. In the last two months, the price increase has been in tune to 40% and further it is expected to go up more. He reasons that the Aluminum prices were undervalued before that, hence it is going through a phase of correction now, and the unexpected price rise is adding up due to the present surge in sea freights. The freight issue is a major contributor as it has increased three times during the last three months.

The scenario in the ACP manufacturing segment is almost the same as it is happening in Melamine and other decorative & panel industries. There is an acute price jump, yet despite the price hike, the raw materials are not available in the market according to the demand.

Mr. Rajesh Shah, Managing Director, Euro Bond said to The Ply Reporter that the prices of raw materials are continuously increasing and the scenario is not going to ease up soon. In the last two months, the overall price rise in raw materials is about 35%. If we do not pass on this price rise to the customers, we will not be able to run the manufacturing establishments for ACP. In December there would be some relief at the price front as the month onwards the burden from the US and Europe market comes down, then only we could have some relief added Mr. Shah.

The entire raw materials such as Coil, PVDF, LDP, Ink, etc prices have gone up exponentially. The ACP industry was contemplating to announce price increase move from 1st Sept but, adding up by coil cost, at least 10% prices will be increased to sustain in the present scenario. The market demand is bullish for ACP hence many of the manufacturers are troubled with only raw material issues. The good demand scenario is helping the good quality ACP manufacturers so far said Eurobond managing director Mr. Rajesh Shah.

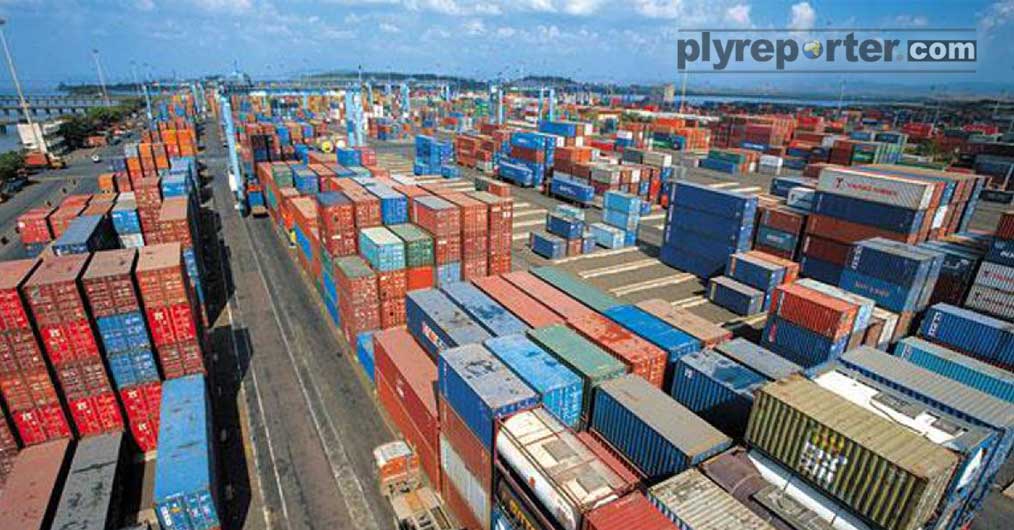

Mr. Nikhil Arora, Director, Virgo ACP said, “Almost every raw material like Aluminium, Resin, Film, etc are noted for the price hikes. This price rise is the highest in the last ten years and there is an expectation that it will go up by 10% more in the coming months. It has a deep impact on the industry as all are sourced from overseas markets. The prime reason for the price hike is containers' non-availability. So the way out is to pass on the cost to markets.

Mr. Nikhil said, “There are reports about three major global plants are under shutdown for their maintenance, that are adding to price rise build up. He added that Virgo ACP Unit in Gujarat, has installed a color coating line and its commercial production will be announced shortly. He said that ‘the price rise in Virgo ACP is effective from 1 September 2021 and it has been accepted everywhere, but we have to increase prices further seeing the increasing prices of Coils.”

The entire raw materials such as Coil, PVDF, LDP, Ink, etc prices have gone up exponentially. The ACP industry was contemplating to announce price increase move from 1st Sept but, adding up by coil cost, at least 10% prices will be increased to sustain in the present scenario.

Mr. Jinesh Gala, Director, Timex Bond said, “There is a lot of instability in the ACP Industry because of the continuous increase in the cost of raw materials. Raw material costs are up by 20 to 25% and are still rising month by month. Practically there is no choice for the manufacturers and dealers/ customers, we all have to just accept this and help each other in this unusual situation.

He further adds that the price of every raw material has increased but Aluminium coil is leading the race. It is currently at its lifetime high and causing a lot of trouble for the ACP Industry. From what we have been witnessing during the last 8-10months, it is very difficult to say if the situation will improve so soon. For now, it will be better if prices at least stabilize and do not keep increasing month by month.

Mr Rajesh Gupta, Nidhi Enterprises – LDP manufacturers views that The ACP industry is affected by rising raw material cost, high operational cost, etc. The prices of LDP granules for ACP have increased on an average of 10% during the last few months. The manufacturing is hit badly with increasing input cost of every raw material. The scrap shortage is also rising thus adding pressure on the main raw material known as LDP grannual or popularly called as Plastic dana’. With shifting supplies to other applications, the cost of plastic waste is rising sharply like in pipes, triple, etc.

Since Aluminum Coils contribute to be approximately 35 to 40 % of raw materials input cost for ACP manufacturing, there is no way other than increasing the prices especially, when the Indian ACP Industry is heavily dependent on imported Coils from China.

Due to the increase in prices of Raw Materials such as Aluminium Coil, PE Granules, Polymer Films, Transportation costs during the last 5 months, ACP Manufacturers Association members decided to re-pricing their products

The ACP Manufacturer Association has announced to increase the prices by 7-10% on different variants of composite panels which are produced with a combination of metal and plastic composites. The majority of players have announced to increase the prices with effect from 1st September 2021.

ACP Manufacturers firmly believe that if the Coil prices have continued to increase they might increase prices of ACP in the coming month.